Haivision’s Makito X series of video encoders and decoders are everywhere, literally. They can be found in broadcast studios, OB vans, sports venues, and testing ranges and are used for a wide range of use cases. Complex broadcast workflows for remote production (REMI) or ISR systems that involve multiple motion imagery sources, may require dozens of Makito video encoders and decoders distributed across multiple locations.

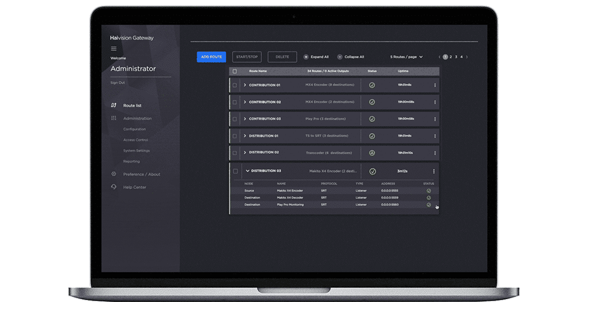

Although each Makito device can be configured remotely via a web browser based graphical user interface (GUI), managing a large number of Makitos all at once, keeping firmware up to date, and keeping track of which device does what, can be daunting. For this reason, we’ve just updated Haivision EMS, our Element Management System, to support the Makito X series and the Makito X4 video encoder. For defense and ISR systems we’ve also added support for the Makito X4 Rugged and Makito X1 Rugged video encoders.

Haivision EMS is designed to be an intuitive element management tool with a similar look and feel to other Haivision products. To demonstrate how easy it is to use, we’ve created a 2-minute video that shows how simple it is to manage multiple types of Makito X video encoders and decoders, create custom labels, organize devices by location, and perform firmware updates.

Real-time Visibility of Devices

As low latency video encoders and decoders, Haivision Makito devices are designed specifically for real-time video, and so is EMS. No matter where the devices are located, it’s possible to quickly view their status and ascertain whether they are operating or not, and if so, for how long, and which devices are turned off or offline. With visibility of all devices in real-time, administrators can quickly troubleshoot any performance issues, no matter where a device is located.

At Haivision, we are continually enhancing our hardware encoders and decoders with software updates to introduce new features. For this reason, we’ve enabled our EMS to update devices remotely. With Haivision EMS, system administrators can quickly verify the firmware of each device, no matter where they are located, and then perform bulk upgrades when necessary. An example of how easy this can be is shown in the video.

To make it easier to keep tabs on where each device is, what workflow component they can be applied to, or any other criteria, users can create up to 100 customs labels. These can then be simply dragged and dropped onto devices to keep track of critical information such as location or function for example. This makes managing complex workflows and advanced systems much easier with Haivision EMS providing a single real-time view of all Makito devices.